Embracing Change: Why Agile Leadership is the Key to Manufacturing’s Future

Understanding the Essence of Industry 4.0

Welcome to the world of Industry 4.0, also known as the Fourth Industrial Revolution! Industry 4.0 is a digital transformation reshaping the manufacturing landscape and integrating advanced technologies like AI, IoT, Big Data, and automation into industrial processes. It is not just about technology but a mindset shift. The challenges are clear: supply chain disruptions caused by natural disasters, geopolitical turmoil, and global pandemics.

As manufacturers, industrial professionals, and individuals interested in technology’s impact on the manufacturing sector, you are not just observers but integral to the solution. Your actions will determine the course of this revolution, and your influence is significant to shape the future of Industry 4.0.

Manufacturers must become more agile, adaptable, and responsive to thrive in this new normal. The goal? Build an organization that’s lean and agile and always ready to learn and evolve in constant change. The urgency of this transformation cannot be overstated, as it is the key to survival and success.

The Challenges of Traditional Manufacturing

The traditional manufacturing model, focused on rigid planning and hierarchical structures, needs help to keep up with the rapid pace of change. Disruptions like global supply chain issues and changing customer demands have highlighted the need for a more flexible, responsive approach.

The top-down approach, where decisions are made at the highest levels and implemented without input from lower-level employees, can suffocate creativity and limit the potential for breakthrough ideas. The traditional focus on efficiency over flexibility makes it difficult for manufacturers to respond to unexpected disruptions.

Why Agile Leadership is Critical in Manufacturing

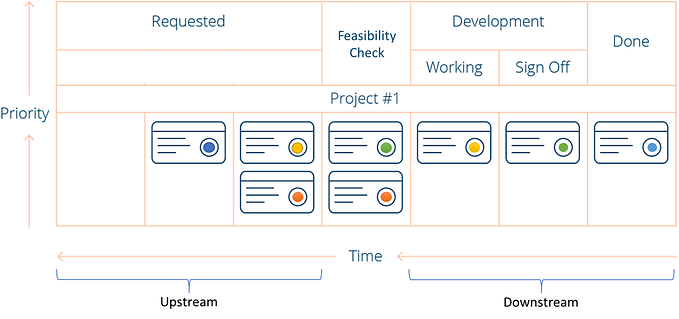

The Agile approach emphasizes flexibility, transparency, and collaboration, which help organizations respond quickly to changes and unexpected challenges.

Think of the Agile Manifesto, which values:

- Individuals and interactions over processes and tools

- Working solutions over comprehensive documentation

- Customer collaboration over contract negotiation

- Responding to change by following a plan

While each element is essential, Agile values those on the left more, creating a mindset perfect for today’s manufacturing landscape. Agile leadership creates a culture where teams are empowered to innovate, experiment, and adapt, making them better equipped to handle the complexities of Industry 4.0. This is not a one-time event; it requires:

- Cultural Shift: Moving from a hierarchical structure to a more collaborative one.

- Skill Development: Equipping employees with the skills needed to work in an Agile environment.

- Technology Adoption: Leveraging tools and technologies that support Agile practices.

- Measurement and Feedback: Regularly assessing progress and making adjustments as needed.

The Step-by-Step Journey Towards Industry 4.0 Excellence

Transitioning to an Industry 4.0 organization isn’t a sudden leap; it’s a step-by-step process. Here’s a roadmap to guide you through:

- Phase 1: Creating Awareness: Start by creating awareness among your key stakeholders about the benefits of Industry 4.0. Understand the technologies involved and how they align with your organization’s goals.

- Phase 2: Conducting a Readiness Assessment: Evaluate your current strengths, weaknesses, and gaps in technology, skills, and culture. This assessment helps build a solid foundation for a roadmap.

- Phase 3: Designing the Roadmap: Develop a detailed plan outlining the sequence of technology adoption, skill development, and cultural transformation initiatives.

- Phase 4: Pilot Implementation: Launch a pilot project on a smaller scale to test selected technologies and methodologies. Use the lessons learned to refine your approach.

- Phase 5: Scaling Up: Once the pilot proves successful, scale up your Industry 4.0 initiatives across various functions and departments. Collaboration across teams is critical at this stage.

- Phase 6: Continuous Improvement: Industry 4.0 is an ongoing journey. Continuous monitoring, feedback, and fine-tuning are essential to maintaining momentum and achieving sustained excellence.

Unlocking the Power of Industry 4.0: Transformative Benefits

As you progress on your Industry 4.0 journey, the benefits become apparent:

- Enhanced Efficiency and Productivity: Automating tasks, optimizing processes, and leveraging data insights drive operational efficiency and productivity.

- Greater Customer-Centricity: Data analytics offer deep insights into customer needs, enabling a more personalized customer experience.

- Improved Decision-Making: Real-time data enables faster, data-driven decisions, reducing risks and seizing opportunities.

- Innovation and Agility: A culture of innovation fosters creativity and the ability to adapt, helping organizations quickly stay ahead of the competition.

- Sustainable Growth: The synergy of efficiency, customer focus, innovation, and agility paves the way for long-term success.

Agile Manufacturing: The Future is Now

Manufacturing is at a crossroads, and the path to the future is clear. With its focus on rapid iteration, operational flexibility, and bottom-up innovation, Agile manufacturing empowers organizations to respond quickly to customer demands and market shifts. Manufacturers can unlock new levels of efficiency and responsiveness by equipping teams with the right tools, skills, and governance.

It’s time to embrace change, foster a learning culture, and leverage data-driven insights to become a truly agile organization ready for the future. However, with so much to accomplish, it’s easy to feel overwhelmed. The key is to remember that transformation doesn’t happen overnight. Focus on what you can handle — bite off as much as you can chew, and take one step at a time, one improvement at a time. This journey is about continuous improvement, making small, meaningful changes that build upon each other. You’ll create sustainable growth and a resilient, adaptable organization by pacing yourself and focusing on incremental progress.

Are you ready to embark on your Industry 4.0 journey? The future of manufacturing awaits!